mdf board used for

Choosing the right material for interior projects becomes much easier once you understand what an MDF board is and what an MDF board used for in real applications. MDF has become one of the most practical materials in modern construction and furniture manufacturing because it is stable, smooth, predictable, and easy to work with. Whether the goal is durability or design flexibility, MDF provides solutions that many other materials cannot match. Learning exactly what MDF board used for helps you select the right product for any design or production task.

Definition of MDF and Its Core Properties

Medium Density Fiberboard is an engineered wood board made by compressing refined wood fibers with resin under controlled heat and pressure. This process creates a smooth, uniform, and dense structure with no knots or unpredictable grain behavior. Because of this consistency, MDF is easier to machine than natural lumber and offers better performance in detailed edging, cutting, drilling, and finishing.

MDF’s strength comes from its internal bond. The fibers interlock tightly, giving it a stable core ideal for cabinetry, furniture frames, wall panels, carvings, and decorative applications. Most MDF boards are compatible with laminates, paints, PVC coatings, and advanced surfaces like high gloss mdf. When selecting a board, buyers often compare density levels, moisture resistance, surface grade, and thickness to match the intended environment.

Manufacturers rely heavily on MDF because it minimizes waste and ensures predictable results during machining. For contractors and designers, MDF offers a balance between cost efficiency and design freedom. It delivers a clean, modern look whether used in homes, offices, retail stores, or large commercial interiors.

Send Your Inquiry

Fill out the short form and our team will get back to you with the details you need.

Quick way to apply

Common Uses of MDF Board

MDF serves dozens of practical roles across interior construction, decorative projects, and furniture production.

A closer look at what MDF board used for reveals its versatility and value across multiple industries.

Kitchen Cabinetry

Kitchen cabinets frequently rely on MDF because of its smooth surface and reliable machining. Paint adheres evenly, and laminated coatings provide a clean, durable finish.

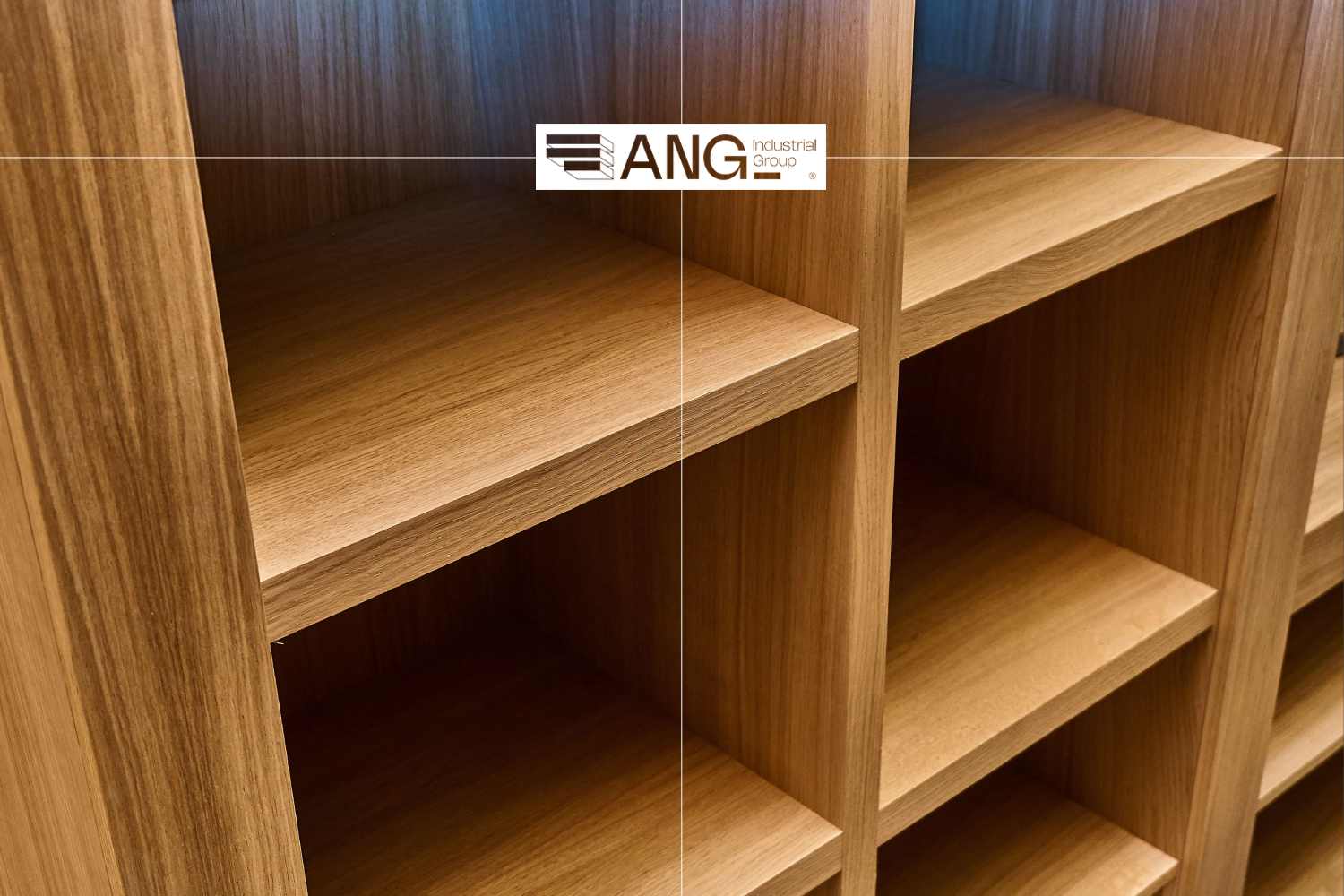

Wardrobes and Closet Systems

MDF panels make wardrobes more stable and visually uniform. They allow precise cutting for doors, shelves, and partitions with minimal edge chipping.

Interior Wall Panels

MDF offers a stable base for decorative wall systems and 3D wall panels. Designers prefer it for modern, geometric, or grooved paneling styles.

Office Desks and Workstations

The board’s uniform density improves the strength of tabletops and ensures long-term durability in office environments.

Retail Shelving and Counters

Retail designers use MDF to build counters, product displays, and shelving systems because it handles weight well and delivers a polished surface.

Doors and Frames

MDF interior doors remain popular for their smooth texture, stable core structure, and compatibility with a wide range of finishes.

CNC Decorative Panels

Carved panels and routed patterns look crisp and detailed on MDF because its fibers respond predictably to cutting tools.

Painted Furniture

Painted MDF furniture benefits from the board’s smooth surface, allowing for flawless color application without visible grain.

Audio Speaker Boxes

Some MDF types perform well in audio systems due to density stability and sound vibration control.

Interior Partitions

Light partitions made from MDF help define space in offices, commercial buildings, and temporary installations.

Decorative Uses of MDF Board in Modern Design

Beyond structural applications, MDF supports creative and decorative design work that enhances interior aesthetics. Its versatility gives designers a wide canvas for experimenting with textures, finishes, and patterns.

High-end interiors use MDF to create seamless wall panels with integrated lighting and hidden joints. Because MDF can be milled into curved, grooved, or fluted forms, it blends functionality with artistic expression. The board’s adaptability supports luxurious designs while remaining affordable for large-scale installation.

In kitchens and living rooms, MDF offers stylish options through laminated surfaces, matte finishes, colored panels, and reflective coatings. The rise of matt and gloss combinations allows designers to shape personalized environments based on modern design principles. MDF’s smoothness is also ideal for minimalist furniture where clean lines and consistent geometry matter.

Custom-built shelves, floating cabinets, media walls, and built-in seating are often crafted from MDF because contractors can easily trim and adjust pieces onsite. This flexibility ensures perfect fit and alignment in every project, a critical feature for precision interior design.

For commercial spaces, MDF delivers a premium look without the cost of solid materials. Restaurants, boutiques, and clinics rely on it to create inviting environments that remain durable and visually balanced. MDF also supports branded designs, custom shapes, and intricate logo work made possible through CNC machining.

Call Us Now.

Our team is ready to assist you and answer your questions right away.

We are available.

Why ANG MDF Is Ideal for Multi-Purpose Use

When understanding what MDF board used for, evaluating the producer becomes essential. The reliability of the board directly reflects the standards of its manufacturer. This is where Ang plays a significant role as a leading provider of engineered panels in Iran.

ANG Industrial Group sources raw MDF from trusted suppliers and enhances every board through controlled lamination, sanding, and finishing systems. Their production lines operate with strict density checks, surface inspections, and continuous quality verification. This consistency ensures that mdf boards from ANG meet the demands of both furniture factories and interior contractors.

ANG produces a broad selection of MDF categories including laminated boards, matte panels, gloss finishes, melamine surfaces, and moisture-resistant variants. Their advanced coating lines deliver stable adhesion, color consistency, and strong surface durability suitable for both decorative and structural use.

For large commercial projects, ANG offers reliable production capacity with predictable lead times. This makes bulk ordering easier for building companies, carpenters, and retail brands that depend on stable supply. International buyers also appreciate ANG’s export support, documentation management, and shipment coordination.

ANG MDF performs exceptionally well in CNC routing, allowing clean edges and detailed designs without fiber tearing. This makes it ideal for wall art, cut-out designs, geometric panels, and custom furniture. Designers who experiment with curved forms or advanced textures rely on ANG boards for their accuracy and strength.

Moisture resistant boards produced by ANG are suitable for kitchens and bathrooms, while their gloss panels support premium design aesthetics. The collection includes colored MDF, UV-coated boards, and fire-rated options for specialized construction needs.

By combining engineering precision with a wide product range, ANG provides solutions for almost every application where MDF can be used.

Conclusion

Understanding what MDF board used for helps professionals choose the right material for each environment, whether it is cabinetry, decorative interiors, furniture production, or modern architectural components. MDF offers stability, smooth finishing, low waste, and impressive design potential. Selecting a reliable producer ensures consistent density, strong bonding, and surfaces that match project requirements.

If you want expert guidance, access to samples, or help selecting the right MDF type for your design or construction project, reach out to a trusted producer and request a consultation. With the right support, choosing the best MDF becomes a simple and confident decision.