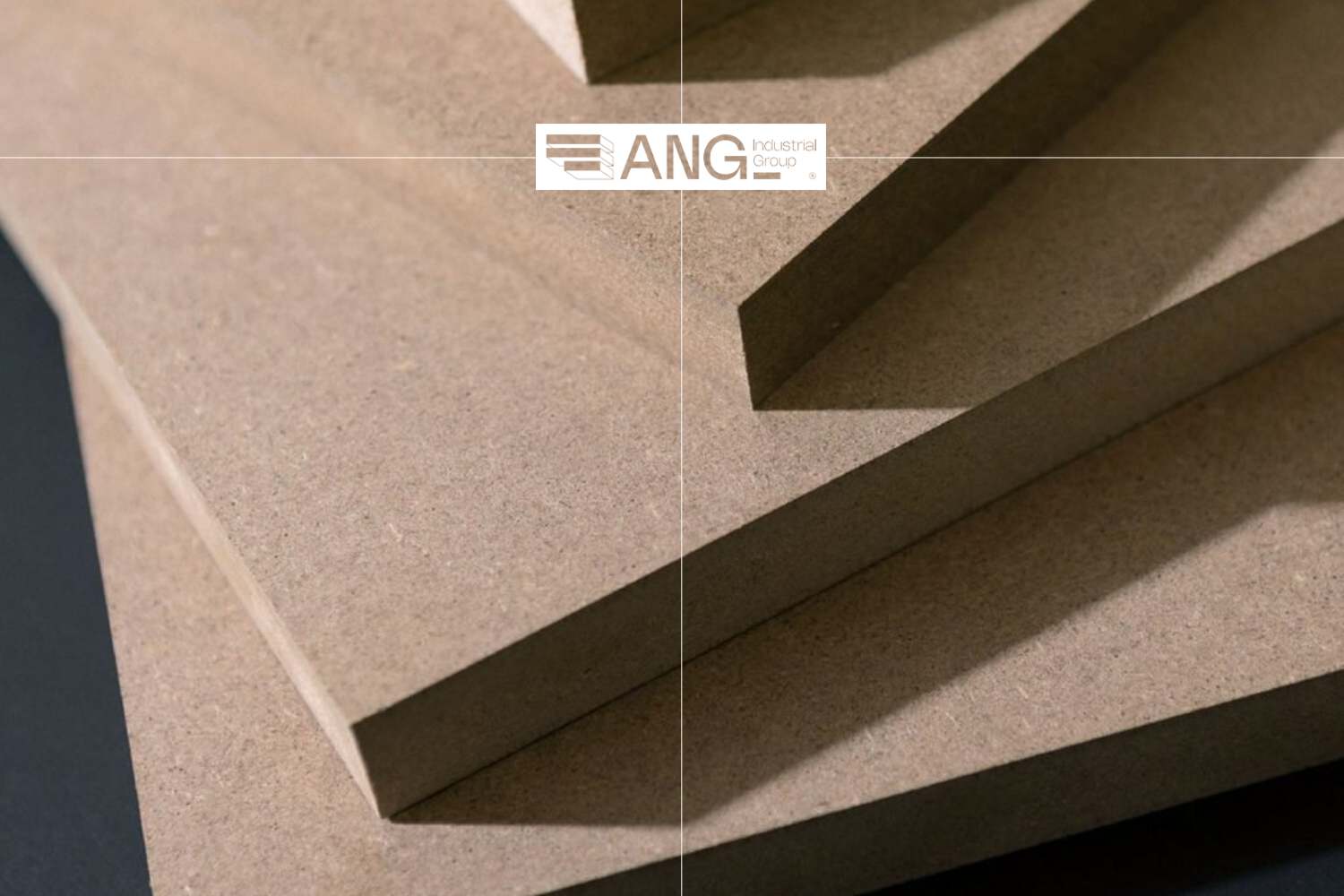

quality mdf

Choosing quality mdf is one of the most important decisions in interior construction and furniture manufacturing. The stability, finishing ability, and long-term performance of every project depend heavily on the panel used as the core material. When the board is engineered with precision, it delivers smooth edges, reliable strength, and predictable results during cutting and coating. Understanding what truly defines quality mdf helps businesses avoid structural issues, reduce waste, and achieve professional results in both small and large projects.

Features of High Quality MDF

best quality mdf panels stand out through a series of engineered traits designed to improve performance, durability, and finishing accuracy. A strong MDF board carries several consistent features that determine its reliability in different applications.

Key Features

- Uniform density across the entire sheet

- Smooth surface free from fiber lumps

- Strong internal bonding due to high-grade resins

- Low formaldehyde emissions

- High screw-holding strength

- Minimal swelling in moderate humidity

- Seamless compatibility with laminates, paints, and coatings

- Predictable machining behavior for CNC work

These features ensure that best quality mdf board performs better under daily use, supports precise finishing, and remains stable in various temperature and humidity conditions.

Send Your Inquiry

Fill out the short form and our team will get back to you with the details you need.

Quick way to apply

Difference Between High Quality and Regular MDF

Regular MDF often suffers from inconsistent density, weak bonding, visible fiber clusters, and unpredictable surface behavior. These issues lead to chipping during cutting, poor adhesion when painting, and reduced durability over time. High quality MDF eliminates these issues by maintaining uniformity from surface to core.

The difference starts in the raw material selection. Premium MDF uses refined wood fibers that create a smooth sheet, while lower-grade options rely on coarse fibers that reduce strength. High quality boards also use stronger adhesives, resulting in a panel that tolerates drilling, sanding, and repeated load stress without cracking.

Thickness accuracy is another point of separation. Regular MDF can vary slightly in thickness, making large-scale installations difficult. Quality grades maintain exact thickness levels, simplifying assembly in kitchens, wardrobes, and commercial interiors.

Moisture sensitivity is also lower in premium boards. This matters in spaces like kitchens or offices, where humidity changes can cause swelling. Businesses that rely on quality MDF experience fewer customer complaints, fewer warping issues, and lower replacement costs.

Materials Used in Quality MDF Production

The properties of high quality mdf depend largely on the raw materials used to create the panel.

Manufacturers combine engineered fibers, resins, and surface coatings to produce durable, stable MDF suitable for various applications.

Refined Wood Fibers

High quality MDF uses purified wood fibers free of impurities, bark, and oversized particles. These fibers create a dense, uniform structure.

Advanced Adhesive Resins

High-strength resins bind the fibers tightly, improving internal bond strength, reducing swelling, and increasing durability.

Surface Coating and Laminates

Producers may use melamine films, PVC foils, or lacquer coatings to create smooth finishes. Some coatings enhance durability, while others focus on aesthetics.

Moisture-Resistant Additives

Certain boards use moisture-resistant chemicals to minimize swelling. This is essential for bathroom vanities, kitchen cabinets, and laundry room furniture.

UV Protective Lacquers

UV lacquer coatings strengthen the board’s surface, making it more scratch-resistant and stable against fading.

Raw materials determine how well the board handles machining, coating, and long-term use. Factories with strong material control produce consistent sheets suitable for mdf board used for decorative and commercial applications.

How to Identify a Quality MDF Board

Identifying a high-quality MDF sheet does not require technical testing equipment. Many signs are visible during inspection or early in the machining process.

Start by checking the edges. Quality MDF has tight fibers with no visible gaps. Boards that crumble easily or shed dust quickly may lack internal bonding strength. The surface should feel smooth to the touch, allowing even coatings of paint or laminate.

Weight is another indicator. Higher density boards feel more substantial, which often means better durability and performance during routing. When cutting, high quality mdf board produces clean, consistent edges. If the sheet chips too easily, the fiber structure is weak.

Good MDF should not bend easily under moderate pressure. It should also show minimal swelling after limited exposure to moisture. Surface compatibility is crucial as well. Laminates, PVC films, matte coatings, and glossy foils adhere better to boards with strong resin bonding and smooth surfaces.

Manufacturers who provide technical specifications, quality certificates, and density reports usually indicate reliable production standards. Working with a trusted supplier such as Ang ensures consistent material quality, which is essential for factories and designers who rely on predictable performance.

Uses of High Quality MDF in Interior and Commercial Projects

high quality mdf wood supports both structural and decorative applications, making it one of the most flexible materials available to interior designers, carpenters, and contractors. Its smooth texture and consistent density help achieve clean lines and durable surfaces in modern construction.

In kitchens, quality MDF serves as the base for laminated doors, shelves, and built-in cabinets. Its stability ensures that hinges remain secure and edges stay straight over years of daily use. The material is ideal for painting as well, delivering a refined look in matte or gloss finishes.

Wardrobes, closets, and bedroom furniture rely on quality MDF for uniform surfaces and easy assembly. Because the board machines cleanly, it supports soft curves, precise cuts, and detailed patterns without splintering.

In office environments, MDF panels support desks, partitions, meeting room furniture, and shelving systems. Their predictable dimensions allow modular builds that require perfect alignment. For retail spaces, MDF produces display units, cash counters, and shelving that withstand heavy daily use.

Decorative wall cladding is another area where MDF excels. Designers use it to create fluted panels, geometric designs, CNC-routed artwork, and 3D feature walls. High density boards maintain crisp edges even after deep routing.

Hotels and restaurants depend on MDF for interior fixtures because it combines elegance with durability. Boards coated with laminate, paint, or protective films create surfaces that are easy to maintain and visually appealing.

Finally, MDF’s compatibility with a wide range of coatings makes it perfect for glossy finishes. This applies especially to premium interiors using high-end mdf boards for a polished, refined appearance.

Call Us Now.

Our team is ready to assist you and answer your questions right away.

We are available.

Best High-Quality MDF Brand in Iran

Among the producers in the Iranian market, ANG Industrial Group remains one of the most reliable suppliers of quality mdf. Their experience in engineered surfaces, laminated panels, and specialized mdf quality production allows them to supply consistent boards to domestic and international buyers.

ANG maintains strict quality control at every step, from raw fiber inspection to final coating. Their advanced facilities in Qom include hot-press machines, sanding lines, laminating systems, and measuring equipment that ensure precise thickness and density.

The company offers a wide range of MDF options including melamine-coated boards, matte finishes, gloss surfaces, moisture-resistant variants, and specialized decorative panels. This variety helps designers and manufacturers choose MDF suited to both commercial and residential applications.

ANG also supports bulk orders for export. With efficient logistics, transparent pricing, and reliable shipment schedules, the company has gained a strong reputation in regional markets. Their MDF is frequently chosen for kitchens, hotels, closets, retail interiors, and large architectural projects.

Their technical team provides guidance on finishing methods, installation techniques, and selecting the right panel based on project needs. This support helps contractors reduce material waste and improve long-term performance in completed installations.